No.

Tied into our current 3D printing boom is a second, equally interesting one: an explosion of accessible 3D scanners. As you may be able to guess from the name, 3D scanners can take physical objects and turn them into digital files. Once you have digitized an object you can modify it, share it over the internet, and/or print it out with a 3D printer.

Like 3D printers, 3D scanners are not new technology. Companies have been making expensive, high quality scanners for years. These scanners could be used to quickly create digital replicas of things like buildings, entire neighborhoods, or even fossilized whale bones that are accurate down to the centimeter (or millimeter). But, also like 3D printers, recent years have started to see low cost, pretty-good scanners enter the market.

There huge variety in these scanners. Microsoft’s Kinect has been hacked and turned into a 3D scanner. 123D Catch from Autodesk can turn a series of regular, 2D photographs into a 3D model. Makerbot has released their own 3D scanner (well, sort of their second 3D scanner), and Kickstarter is chock-a-block full of handheld 3D scanners, desktop 3D scanners, and dongles that turn your phone or tablet into a 3D scanner. Back in 2011 we even did a podcast interview with the inventor of Trimensional, an iPhone app that used light from the iPhone’s own screen to create a 3D model.

All of which is to say that pretty soon anyone who wants access to a reasonably high quality 3D scanner will have one. In fact, anyone with a smart phone in their pocket will have one whether they want it or not.

A Crisitunity?

Most people will see this as an exciting opportunity. Imagine if on your next vacation, instead of just taking a picture of yourself next to the Elgin Marbles you scan them so you can print them out at home. Or going to a botanical garden, scanning a bouquet worth of flowers, and mixing them into a 3D printed statue for your sweetheart. Being able to capture the world in 3D will present us all with incredible opportunities.

Of course, some people will see this new technology as a crisis. They will worry that being able to copy objects means being able to copy objects without permission. And that could mean infringing on copyright (of course in many cases the objects being copied will not actually be protected by copyright, but let’s set that aside right over here for now). They will conclude that this type of technology is just too dangerous to be freely available, and insist on some combination of digital and legal restrictions that make it much less useful and much easier to control.

A Dumb Response

This type of response is, in a word, dumb. Yes, it is true that 3D scanners can copy physical objects. And it is true that some of those physical objects will be protected by copyright (or patent). And, furthermore, it is true that some of those protected objects will be copied without permission, therefore infringing on their respective copyrights and patents.

But that alone is not enough to build a case to restrict them. After all, you can say pretty much the same thing about digital 2D cameras. Digital cameras make copies of all sorts of copyright-protected things every day. Many of those copies are made without permission. And, at least on some level, that is a problem.

But no one would suggest that the correct response to that problem is to build limitations into digital cameras. Or hold digital camera manufacturers responsible for copyright infringement. There is no reason to treat 3D scanners any differently.

So enjoy those 3D scanners. Use them responsibly. Or at least as responsibly as you use your 2D camera. And if someone starts freaking out about how 3D scanners will somehow mean the end of intellectual property as we know it, tell them to take a deep breath. Sit them down. Scan their face. Turn it into a 3D printed mug and fill that mug with whatever liquid you think will best help them to relax.

What is Going on With Usage Restrictions on Media from Congress and the White House?

The White House and Congress are trying to restrict use of public domain photos and videos.

As two of the three branches of the US government, Congress and the Administration have key roles in creating and enforcing our copyright law. So why are they trying to restrict what people do with public domain material?

Believe it or not, copyright law actually has a specific section addressing the Federal Government’s ability to get a copyright. The section is pretty straightforward: the Federal Government does not get copyright on the works that it produces. You don’t need to be a lawyer to understand the first part of 17 U.S.C. § 105:

Copyright protection under this title [which pertains to copyright] is not available for any work of the United States Government.

This means that works created by the US Government receive no copyright protection. These works do not pass go nor do they collect $200 – they automatically enter the public domain the moment they are created, freely available for anyone to do whatever they want with them. And yet strangely there are parts of the US government that do not seem to understand that.

This is not new. Back in 2009 our friends over at Creative Commons and EFF pointed out that the official White House flickr stream was using a CC-Attribution license – a license that requires some sort of underlying copyright to enforce. To their credit, shortly after this concern was raised, the White House and flickr responded to this criticism and made it clear that the works are in the public domain.

Those United States Government Work “licenses” still appear on White House Flickr photos. But the licenses are not alone. They are joined by a prominent alert:

This official White House photograph is being made available only for publication by news organizations and/or for personal use printing by the subject(s) of the photograph. The photograph may not be manipulated in any way and may not be used in commercial or political materials, advertisements, emails, products, promotions that in any way suggests approval or endorsement of the President, the First Family, or the White House.

What? This extra language has been noted multiple times, but for some reason persists. Whenever you see a restriction like this, the first question you should ask yourself is “or what?” What happens if I use these photos outside of the scope of the restriction? In most cases, if you saw this type of restriction the “or what” would be “you will be sued for copyright infringement for exceeding the scope of this license.”

But without copyright protection, that “or what” is simply not available. The White House is not explicitly claiming copyright on these photos (the license makes that clear), but this type of scary quasi-legal language gets awful close to flirting with a bit of light copyfraud. I could reproduce entire photos here on the PK blog – neither the site for a news organization nor my personal website - without fear of any sort of repercussion. See:

I can even manipulate them in express violation of the alert:

The White House clearly understands its relationship to copyright. The copyright policy of whitehouse.gov makes it clear that nothing that the White House generates for the site is protected by copyright. And the White House YouTube channel makes it clear that its videos are in the public domain and even makes it easy for you to download them.

So what’s so special about photographs in the Flickr stream?

Unfortunately, the White House is not alone in this game. The House Judiciary Committee streams and archives its hearings here and the page includes this restriction:

Use restriction: No portion of any recording may be used for a political purpose; no portion of a recording may be disseminated with commercial sponsorship except as part of a bona fide news program or public affairs documentary; no portion of a recording may be used in any commercial advertisement; and any redistribution must be subject to this same notice.

The House Government Oversight Committee does not have a lengthy use restriction on itsYouTube page. But instead of a public domain notice with a download button it applies a “Standard YouTube License” to archived videos of its hearings.

With no underlying copyright to license, that license is meaningless – although it may stop someone who has not read section 105 from making use of video in the public domain. The House Energy and Commerce Committee does the same thing. Members are just as guilty. Representatives Goodlatte, Watt, Blackburn, and Conyers – all of whom are heavily involved in copyright issues – slap licenses on videos that are not protected by copyright.

The Senate is no better. Videos on the Senate Commerce Committee YouTube channel are licensed under a “Standard YouTube License.” So are the Senate Budget Committee’s videos. Ditto for videos from Senators involved in copyright policy like Senators Leahy, Hatch, andFeinstein. All of them leave the public under the false impression that they need some sort of permission in order to make use of these videos.

This may all seem like legalistic quibbling, but it is not. There are many members of Congress who think it is important to educate the public about copyright, but it seems that no one has thought to start with videos that Congress itself releases. The same applies for photos released by the White House. Worse, bogus use restrictions imply that the American public is not free to use the works that its government is producing on their behalf.

Fortunately, this is an easy one to fix. Get rid if bogus use restrictions on photos and videos. Make use of public domain licenses on online services. And if an online service does not allow for a government work-type license, make use of the comments. Tell the public that they are free to make use of the work however they want. After all, that’s the law.

Admitting 5 Things About Broadband

Expanding on The Switch’s 5 things that neither side of the broadband debate wants to admit.

Over at The Switch today, Timothy B. Lee offered his list of 5 things neither side of the broadband debate wants to admit. His list strikes me as mostly reasonable, although I think that you could find at least one side of the debate to endorse most of them. In any case, I wanted to take a moment to add a bit of color to the list, to try and give you a sense of how we think about some of these things. Here are Lee’s things, followed by a bit of commentary.

Over at The Switch today, Timothy B. Lee offered his list of 5 things neither side of the broadband debate wants to admit. His list strikes me as mostly reasonable, although I think that you could find at least one side of the debate to endorse most of them. In any case, I wanted to take a moment to add a bit of color to the list, to try and give you a sense of how we think about some of these things. Here are Lee’s things, followed by a bit of commentary.

1. American wireless service is working pretty well.

Especially when compared to the wired broadband market, this statement is fairly accurate. We have four nationwide carriers and some decisions (like offering earlier upgrades) by one carrier clearly push the other carriers to match.

I would add two additional data points to that statement, however. Lee mentions that, in 2007, there was a great deal of concern about wireless carrier control over mobile software. He then points out that Apple’s decision to open up the iPhone to third party developers rendered the concern “obsolete.” While no one would argue that the state of mobile software has improved massively since 2007, I don’t know that I would go so far as to say that concerns about network operator control are necessarily obsolete. Even today we have carriers preventing some types of services from running on phones connected to their network. And carriers are still working hard to prevent you from unlocking the phone that you own from their network.

Moreover, this state of working pretty well was not necessarily the wireless industry’s destiny. As we have pointed out before, the FCC’s decisions to reject mergers and signal that it would support four competitive nationwide carriers have done a great deal to preserve the level of competition we have today. That does not undercut Lee’s point, but it is worth keeping in mind.

2. We’re falling behind on residential broadband.

It won’t come as a surprise that we’re quite willing to admit that one. The theory of facilities-based competition between telephone companies, cable companies, satellite providers, and even power companies has turned out to be weak in practice. While, as Lee points out, some like to point to DSL or satellite as viable competitors, the reality is that they are not. Coming to terms with this state of affairs would bring us a huge way towards developing rational broadband policies.

3. We desperately need more broadband experimentation.

Again, we’ll admit this one too. Our allies at the Institute for Local Self Reliance do fantastic work trying to help localities build their own local networks and push back against statewide bans on such experimentation.

On the flip side, we get wary that “experimentation” can also be interpreted as an excuse for existing ISPs to inject themselves into the value chain through data caps or special priority fast lanes. In a world with limited broadband competition (see point 2), there are few market protections for consumers with ISPs who want to experiment by exploiting their control over customers. This does not mean that ISPs should not be prevented from experimenting. But these types of concerns should be kept in mind when thinking about those experiments.

4. Discrimination concerns are mostly about video streaming.

This strikes me as sort of, but not totally, true. Video streaming gets a lot of attention these days. In part, this is because video is one of the most data-intensive applications that most people will use on a regular basis. Therefore it is an easy way for people to understand more general concerns about discrimination.

Of course, there are also some video-specific discrimination concerns. As Lee points out, most Americans connect to the internet through their cable provider. And the role of competitor to online video and keeper of a key ingredient to the success of online video can create some problems.

But video is not the only potential victim of discrimination. The internet moves quickly and new applications can seemingly emerge over night. While I don’t know what it is, it is not hard to imagine a whole new generation of data-intensive applications that could be just as vulnerable to discrimination as online video is today. So while the discussion is about video today, that doesn’t mean that it will be about video tomorrow.

5. “Network neutrality” probably isn’t the answer.

Again, this is one that I agree with in part and disagree with in part. I agree that network neutrality is not the only answer. One of the reasons that we started WhatIsNetNeutrality.orgwas to remind people that net neutrality is actually a fairly specific thing, and that “net neutrality violation” was not just synonymous with “a bad thing happening on the internet.” There are going to be a number of developments that raise concerns about internet access but have nothing to do with net neutrality.

That being said, net neutrality is an answer to some of those concerns. Net neutrality rules helped to resolve the dispute surrounding AT&T’s decision to block the Facetime app for some of its customers. Perhaps more tellingly, last week Verizon explained that the FCC’s net neutrality rules were the only thing preventing it from trying to force some websites and services to pay to get special access to its customers. I’m pretty confident that the existence of net neutrality are at least part of the reason that problematic behavior has migrated to other places in the network.

Those quibbles aside, Lee’s five things feel like they are in the right neighborhood to me. Perhaps most importantly, they serve as an important reminder to move beyond that state of play in 2003. We at Public Knowledge work hard to keep abreast of the evolving technical and business reality of the internet and to adjust our advocacy accordingly. But it never hurts to get another reminder that things evolve and that we need to as well.

Original image by Flickr user SweetKaran.

Read More...Takeaways and Next Steps From the Open Hardware Summit

Last week I had the opportunity to participate in the Open Hardware Summit, an event that is always a highlight of my conference year. Now in its fourth year, the summit is a chance for the robust community that has grown up around open source hardware to come together, discuss what has been happening, and show off great advances.

By any measure, the open source hardware community is thriving. Each year the summit gets bigger, the projects and products get more ambitious, and the barrier to entry is lowered. But this year it did feel like the community was reaching an inflection point. The world of open source hardware is expanding beyond its original borders, and that presents its own set of challenges and opportunities. While I raised some of these during the panel that wrapped up the summit, I wanted to expand upon a few of them a bit more.

The State of Licensing and the Law

I touched on this in a blog post last year, and it was the topic of my presentation this year, but my discussions with people at the summit made me think about this further. While open source hardware looks to open source software for inspiration and guidance, from a legal standpoint it must strike out on its own. Fundamentally this is because, in contrast to software, most hardware is not protected by any type of intellectual property.

This can lead to a tension. There are people who are interested in creating “sticky” licenses for open source hardware – licenses that would force people who build upon open source hardware to be open as well. Unfortunately, without an intellectual property hook, those licenses simply are not enforceable.

The way to resolve this tension is not to find a novel way to protect hardware with existing intellectual property law, or to create a new type of intellectual property law that is easier to apply to hardware. For every person who used this right to share designs, there would no doubt be 100 or 1,000 who would use it to reduce sharing.

Instead, it is to find alternatives. Clear, non-legal descriptions of expectations may not be legally binding, but they will make it easy for good actors to play by the rules. Legal enforceability is nice, but it is not the only way forward. There can be a lot of power in publicly calling someone out for violating the rules.

Letting New People In and Allowing Existing People to Evolve

You cannot effectively enforce the rules until those rules are clear to everyone. There have been important attempts to help codify what it means to be open source hardware. Phillip Torrone has written the {unspoken} rules of open source hardware, a strong effort to document some of the informal understandings that have grown up over time. The open source hardware definitionand best practices, hosted and developed by the fantastic Open Source Hardware Association, are also a huge step forward. We need more of this.

But to many people, the heart of open source hardware can still feel like a set of gut instincts, community expectations, and hidden rules that are all too easy to run afoul of. If you are not someone who has already spent a good amount of time in the community, sometimes it can feel like there are unwritten rules just waiting to be inadvertently broken.

For those already deep into the open source hardware community, this may not feel like a problem. But for a community interested in expanding and evolving, it could be.

Here is one, but certainly not the only one, way that the lack of clarity can play out. Over the course of the summit I spoke with a number of people who work for large companies. These individuals (and presumably their companies) were excited, or at least intrigued, by open source hardware. I had no reason to believe that their desire to help their companies go open source was not totally sincere.

But, for all their enthusiasm and interest, they were a bit concerned. They understood that the open source hardware community is a passionate one, and that they would only get one chance to make a first impression. But they were not totally sure how to make sure that first impression was a good one. As a result, the fear of crossing a hidden line may keep them out of open source hardware entirely.

Depending on your perspective, this is either a good thing or a bad thing. There are plenty of people who don’t really care if large companies engage with open source hardware. And that is a totally reasonable position to have. But for people who are at least intrigued by the idea of having large companies embrace open source hardware, this feels like a missed opportunity. Giving newcomers – even corporate newcomers – greater certainty that the rules are clear will help expand the open source hardware world.

Moving Forward

The bad news is that neither of these challenges can be solved by an arduino robot or flashing LEDs. They are the kind of unglamorous infrastructure and community building work that feel a bit like documentation – always behind something else on the todo list.

Furthermore, there is nothing that says that anyone has to do any of it. The world doesn’t end if the open source hardware community does not figure out an alternative licensing solution. Similarly, nothing explodes if the only way to really “do” open source hardware is to hang around in the community for a while first.

Nonetheless, I think not working harder on those things would be a shame. But I could be wrong. And I’m happy to be wrong. My real hope is that if neither of these things happen it is because there was some sort of conscious decision not to let them happen. While I think it would be a missed opportunity not to do them, the real missed opportunity would be to not do them without even realizing it.

But For These Rules…

According to Verizon, the FCC’s Open Internet Rules are the only thing preventing ISPs from becoming gatekeepers for the internet. For background on yesterday’s hearing, start here, for a summary of the arguments go here, and for a timeline of net neutrality, click here.

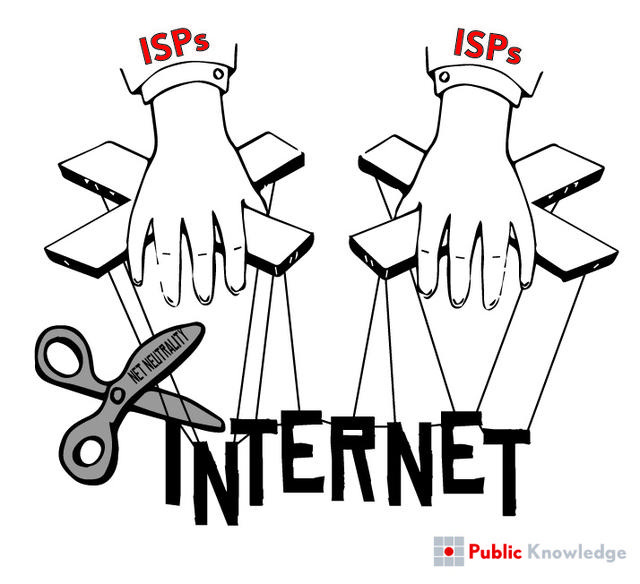

Yesterday Verizon explained, in the simplest terms possible, why net neutrality rules are so important: the rules are the only thing preventing ISPs from turning the internet into cable TV.

During yesterday’s oral argument, the judges and Verizon’s attorney discussed Verizon’s desire to enter into special commercial agreements with “edge providers.” Edge providers are just another name for websites and services – everyone from Google, Netflix, and Facebook to the Public Knowledge policy blog.

These types of agreements – where ISPs charge edge providers extra just to be able to reach the ISP’s subscribers – are exactly the types of agreements that raise network neutrality concerns. If Verizon – or any ISP – can go to a website and demand extra money just to reach Verizon subscribers, the fundamental fairness of competing on the internet would be disrupted. It would immediately make Verizon the gatekeeper to what would and would not succeed online. ISPs, not users, not the market, would decide which websites and services succeed.

Fortunately, we have rules that prevent this type of behavior. The FCC’s Open Internet rules are the only thing stopping ISPs from injecting themselves between every website and its users. But you don’t need to take Public Knowledge’s word for it:

That’s Verizon’s attorney yesterday. “These rules” are the FCC’s Open Internet rules. “Those commercial arrangements” are arrangements that would force edge providers to pay ISPs a toll every time one of the ISP’s subscribers wanted to access the edge provider’s content. In other words, if your ISP doesn’t have a special deal with the website you want to visit (or if the website you want to visit is in a “premium” tier that you haven’t paid for), it may not work.

The FCC’s Open Internet rules prevent that type of corrupting market from developing. Again, Verizon’s attorney:

All of this is good news for those of us in favor of net neutrality. The FCC’s Open Internet rules really are the only thing preventing ISPs from installing themselves as the gatekeepers of the internet. And if you don’t believe us, just ask Verizon.

Bonus: The excerpts above come from a slightly longer exchange between Verizon and the judges anchored in a discussion of standing. The full exchange can be found below. Remember that a “two-sided market” is one in which, in addition to charging subscribers to access the internet, ISPs get to charge edge providers on the internet to access subscribers as well.

And here is a link to a recording of the entire argument.